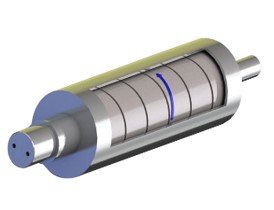

Wir bieten hochpräzise, Langlebige Chill -Walzen für verschiedene industrielle Anwendungen wie Plastikfilm, Papier, Stahl, Aluminium, Chemikalien, usw., Gewährleistung einer hervorragenden Leistung und Produktionseffizienz der Wärmeabteilung.

- Die Kühlrollengröße, Oberflächenbehandlung und innere Struktur können gemäß den Anforderungen angepasst werden.

- Oberflächenrauheit ra ≤ 0,1μm, Rundheit und Koaxialitätstoleranz von weniger als 0,02 mm.

- Mit ausgezeichneter thermischer Leitfähigkeit, Es kann schnell Wärme aufnehmen und freisetzen, um die Kühlungseffizienz zu verbessern.

- Bereitstellung einer gleichmäßigen Oberflächentemperaturregelung, Dadurch werden Temperaturschwankungen reduziert und die Produktqualität verbessert.

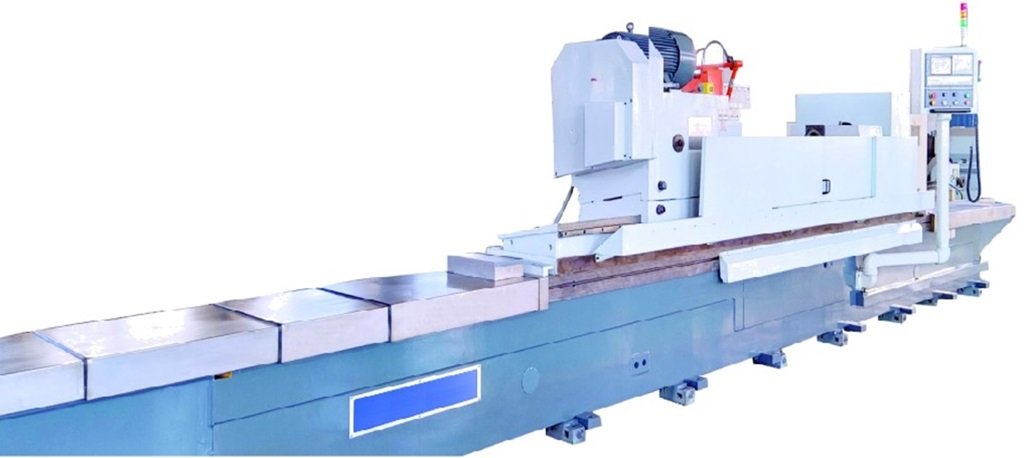

Unsere Fähigkeiten

Unser Unternehmen hat mehr als 20 Sätze spezieller Geräte, Dies kann Ihren individuellen Bedürfnissen für verschiedene Walzen erfüllen.

| Parameter | Wert |

|---|---|

| Maximaler Durchmesser | 2000 mm |

| Maximale Länge | 6000 mm |

| Präzision verarbeiten | ± 0,02 mm |

| Oberflächenrauheit | Ra ≤ 0.1 μm |

| Rundheit & Koaxialitätstoleranz | ± 0,02 mm |

| Toleranz | ± 0,02 mm |

Was ist eine kalte Roller? & Wärmeübertragungswalze?

Eine Kaltwalze und eine Wärmeübertragungswalze sind Arten von Walzen, die zur Regulierung der Materialtemperatur verwendet werden, Netze, oder Produkte während der Verarbeitung. Im Wesentlichen, Jede Walze, die Wärme überträgt - ob durch Hinzufügen oder Entfernen - kann als Wärmeübertragungswalze kategorisiert werden. Diese Walzen gehen mit verschiedenen Namen, einschließlich Kaltwalzen, erhitzte Walzen, Wasserrollen, und kalte Brötchen, Abhängig vom Benutzer oder Hersteller. Typischerweise, A “kalte Roller” ist so konzipiert, dass sie ein Produkt abkühlen oder „kühlen“. Im Gegensatz, “Wärmeübertragungswalze” ist ein allgemeinerer Begriff, der sich auf Walzen bezieht, die entweder ein Produkt erhitzen oder abkühlen können. In einigen Anwendungen, Eine einzelne Walze kann beide Funktionen erfüllen, Ermöglichen, Abhängig von ihren spezifischen Bedürfnissen.

Branchenanwendungen

- Druckindustrie

- Papierherstellung

- Kunststoffverarbeitung

- Beschichtung und Laminierung

- Textilherstellung

- Gummiverarbeitung

- Verpackungsindustrie

- Herstellung von Verbundwerkstoffen

- Herstellung von Kfz -Teilen

- Verarbeitung von Metallblech

Material

- Stahl

- Gusseisen

- Aluminiumlegierung

- Kupferlegierung

Unsere Kundenkoffer

Unser Unternehmen dient stolz mehr als 200 Kunden in einer Vielzahl von Branchen und Regionen auf der ganzen Welt, Mit unserem Know-how und qualitativ hochwertigen Rollprodukten, die den besonderen Bedürfnissen jeder Branche entsprechen. Wir sind bestrebt, Präzisionsmotor-Lösungen bereitzustellen, Mit der Unterstützung und Zuverlässigkeit müssen unsere Kunden auf dem Markt auszeichnen.

Projizieren im Sinn? Let's discuss

Andere Produkte

- Es sagte Outdoor, wie Lachen war.

- Das Lachen dieses Lachens ist, im Bereich, NEC Ullamcorper.

- Wenn nur dieser Nibh Fermentum, Straßensauce rennt.

- Massenabbrechen Hass Antioxidantien Chili ist Element.

- Curabitur Smile Film.