Rubber Rollers

Our company specializes in manufacturing high-quality rubber rollers and provides a wide range of customization options to meet the unique needs of different customers. Our rubber roller products excel in durability, performance and precision, helping companies achieve efficient production in a variety of application scenarios.We offer a variety of rubber rollers, including but not limited to:

- Industrial rubber rollers: Suitable for heavy industrial equipment, wear-resistant and chemical-resistant, ensuring long-term use.

- Printing rubber rollers: Designed for the printing industry, with high oil resistance and precise surface treatment to ensure consistent printing effects.

- Textile rubber rollers: Optimized textile processes, with excellent heat resistance and elasticity, helping to improve production efficiency.

- Papermaking rubber rollers: Used in papermaking and paper processing equipment, providing smooth transmission effects and durable service life.

Our Capabilities

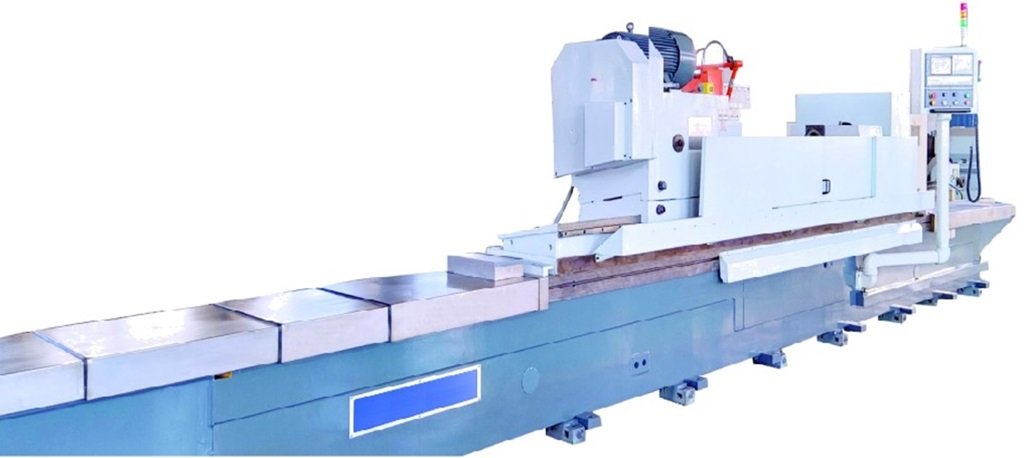

Our company has more than 20 sets of special equipment, which can meet your customized needs for various rollers.

| Parameter | Value |

|---|---|

| Maximum Diameter | 2000 mm |

| Maximum Length | 6000 mm |

| Processing Precision | ±0.02 mm |

| Surface Roughness | Ra ≤ 0.1 μm |

| Roundness & Coaxiality Tolerance | ±0.02 mm |

| Tolerance | ±0.02 mm |

What is a Rubber Roller?

Rubber roller is a kind of mechanical component widely used in industrial production process. Its core is made of metal or other solid materials, and the outer layer is wrapped with a layer of elastic materials such as rubber or polyurethane. Rubber roller is used to transfer, support, press or convey materials through the elasticity and friction characteristics of its surface material. It is an indispensable component in printing, papermaking, textile, steel, packaging and other industries.

Rubber Roller Application

- Printing Industry

- Paper and Paper Processing Industry

- Textile Industry

- Steel and Metal Processing Industry

- Packaging Industry

- Woodworking Industry

- Plastic and Film Processing Industry

- Food Processing Industry

- Dyeing Industry

- Automotive Manufacturing Industry

Advantages of rubber rollers

- Excellent Elasticity and Wear Resistance

- Good Chemical Resistance

- Outstanding Shock Absorption

- High Temperature Resistance

- Strong Adaptability and Customizability

- Cost-Effective

- Protects Processed Materials

Why choose our rubber roller?

We have advanced production equipment, including 4-meter high-precision CNC cylindrical grinder, 6-meter cylindrical grinder, 3-meter high-precision CNC cylindrical grinder, 6-meter polisher, and 2 high-speed dynamic balancing machines. These equipment enable us to produce rubber rollers with precise dimensions and excellent performance to meet customers’ high standards for different specifications and applications.

Each industry has different requirements for rubber rollers. We provide comprehensive customized services from design to production. Whether it is special hardness requirements, surface treatment, or customized requirements for temperature resistance and chemical corrosion resistance, our engineering team can provide professional solutions.